R63A/R80A/R100A/R125A Series Radial Servo Power Tooling Turret

Original price was: $6,200.00.$6,000.00Current price is: $6,000.00.

R63A/R80A/R100A/R125A Series Radial Servo Power Tooling Turret

| Item | Details |

|---|---|

| machinery test report | Provided |

| application | MILLING CUTTER |

| video outgoing-inspection | Provided |

| core components | Bearing, motor, Gear |

| weight (kg) | 150 |

| Center height of turret | 63mm/80mm/100mm/125mm |

| Number of tool-path | 8/ 12 |

| Power tool speed | 6000/5000/4000/3500 |

| Rotating time(included locking) | 0.23/0.35/0.42/0.84 sec |

| Total indexing time for 180 | 0.55/0.76/0.83/1.56 sec |

| Clamping force | 1700/2600/3500/5200 kg |

| Hydrualic working pressure | 3.5+/+0.5 Mpa |

| Flow rate | 18/20/25/30 L/min |

| Inertia of movement for tooi-dis | 0.5/1.5/4/7 |

| Accuracy of repeatability | +/-1.6 |

Description

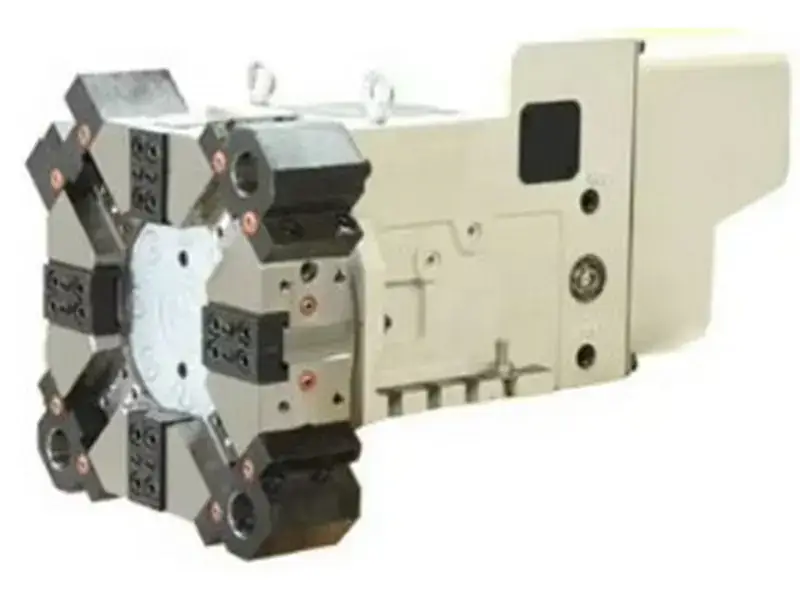

R63A/R80A/R100A/R125A Series Radial Servo Power Tooling Turret

R63A/R80A/R100A/R125A Series Radial Servo Power Tooling Turret: Advanced Performance for Precision Machining

The R63A/R80A/R100A/R125A Series Radial Servo Power Tooling Turret represents a pinnacle of engineering excellence, built on the foundation of the SLT servo turret and enhanced with a radial power module of combined structure. This innovative design results in a compact layout and reasonable structure, making it a versatile and high-performance solution for CNC lathes and turning centers across industries such as automotive, aerospace, and precision engineering.

One of the key features of this turret series is its three-piece precision end gear disc paired with a hydraulic locking device. This combination ensures high positioning accuracy, strong rigidity, and exceptional reliability—critical attributes for handling complex machining tasks. The precision gear disc guarantees minimal positional error during indexing, while the hydraulic locking device delivers robust clamping force, keeping tools securely in place even during heavy cutting operations. This stability is essential for maintaining consistent machining quality, especially when working with hard materials or performing aggressive cuts.

Power for the tools is provided by an independent power motor, which offers high torque output and operates with low noise. The modular interface of the motor allows for easy adaptation to various servo motors, enhancing the turret’s compatibility with different machine tool setups. This flexibility ensures that manufacturers can integrate the turret into their existing systems without extensive modifications, streamlining the upgrade process and reducing downtime.

Each workstation in the R series turret can be fitted with a power tool holder, providing power exclusively at the active workstation. This design optimizes energy usage and reduces unnecessary wear, while supporting a range of tool holders. It is compatible with BMT40, BMT45, BMT55, BMT65, and BNT75 tool holders that conform to Doosan corporate standards, and the coupling interface adheres to DIN1809, ensuring broad compatibility with industry-standard tools. This versatility allows the turret to handle a wide array of machining operations, from simple turning to complex milling and drilling tasks.

Delving into the serialization parameters, the R series offers center heights of 63mm, 80mm, 100mm, and 125mm, catering to different workpiece sizes and machining requirements. The number of workstations varies, with 8 or 12 stations for the R63A and R80A models, and 12 stations for the R100A and R125A, providing ample capacity for diverse tool inventories.

In terms of performance, the power tool speed ranges from 3500rpm for the R125A to 6000rpm for the R63A, enabling efficient material removal across different applications. The rotating time (including locking) for adjacent tool positions is as fast as 0.23 seconds for the R63A, while the total indexing time for 180° (including locking) reaches 1.56 seconds for the R125A, ensuring rapid tool changes and minimal downtime.

Clamping force is impressive across the series, starting at 1700kg for the R63A and reaching 5200kg for the R125A, highlighting the turret’s ability to handle heavy cutting forces. The hydraulic working pressure is consistent at 3.5±0.5MPa, with flow rates ranging from 18 to 30 L/min, ensuring reliable power delivery.

Precision is a hallmark of the R series, with an indexing accuracy of ±4” and a repeatability accuracy of ±1.6” across all models, guaranteeing consistent results even after repeated use. The maximum power of the drive motor (S3-40%-10min) ranges from 2.2kw for the R63A to 7.5kw for the R125A, with a motor-to-tool transmission ratio of 1:1, ensuring efficient power transfer.

The weight of the turret (including the tool disc, excluding the power motor) ranges from 103kg to 245kg, balancing structural stability with ease of integration. With a mean time between failures (MTBF) of 25000 hours, the R series demonstrates exceptional durability, making it a cost-effective investment for long-term production needs.

In summary, the R63A/R80A/R100A/R125A Series Radial Servo Power Tooling Turret combines precision, power, and versatility to meet the demands of modern machining. Its advanced features, robust performance, and broad compatibility make it an invaluable asset for manufacturers seeking to enhance productivity and quality in their operations.