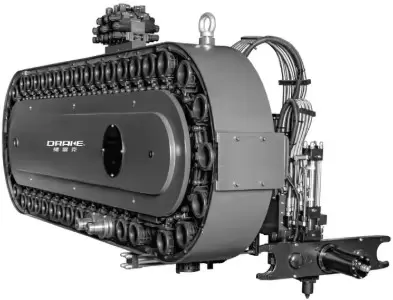

Horizontal Disc Tool Magazine BT40/BT50

Original price was: $19,000.00.$18,000.00Current price is: $18,000.00.

Horizontal Disc Tool Magazine BT40/BT50

| Item | Details |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| weight (kg) | 15 |

| Tool capacity | 16T / 20T |

| Tool change time | 1.3sec / 50hz |

| Max. tool weight | 8kg |

| Max. tool diameter( full loaded) | 75/150mm |

| After-sale Service | Online Support |

| Magazine Speed | 0.25 |

| Tool magazine mode | random |

| Tool change selection | roller gear cam |

| Pocket spec | BT40/CAT40/DIN40/HSK63 |

Description

Horizontal Disc Tool Magazine BT40/BT50

Horizontal Disc Tool Magazine: Precision and Reliability for Efficient Machining

In the competitive landscape of modern manufacturing, where speed and accuracy are vital, the Horizontal Disc Tool Magazine emerges as a precision-engineered solution designed to enhance the performance of CNC machining centers. This compact and reliable system integrates innovative mechanisms with high-quality components, making it an ideal choice for industries that demand consistent tool handling and efficient production workflows.

A defining feature of the Horizontal Disc Tool Magazine is its double roller cam dividing mechanism, which sets it apart with high dividing accuracy and a low failure rate. This advanced mechanism ensures precise positioning of tools, minimizing errors during tool changes and enhancing overall machining precision. Its robust design also contributes to a long service life, reducing the need for frequent maintenance and ensuring uninterrupted operation—key factors for high-volume production environments where downtime can be costly. The compact structure of the magazine further adds to its appeal, as it optimizes space utilization in the workshop, making it suitable for integration into various machine tool layouts.

The tool magazine is equipped with fully imported engineering plastic knife holders, which offer a winning combination of light weight, high strength, and resistance to damage. Unlike traditional metal holders, these plastic holders reduce the overall weight of the system without compromising on durability, allowing for smoother and more energy-efficient operation. Their robust construction ensures that tools are securely held in place, even during rapid movements, while their resistance to wear and tear extends their lifespan, reducing replacement costs over time.

Another notable feature is the separate knife arm, which delivers high concentricity and low noise during operation. This design ensures that tools are aligned with exceptional precision, minimizing vibrations and enhancing the accuracy of machining processes. The low noise level is a valuable asset in busy manufacturing facilities, contributing to a more comfortable working environment and reducing noise-related stress for operators. Together, these features make the tool change process not only precise but also efficient and user-friendly.

The entire series of electronic switches in the Horizontal Disc Tool Magazine uses imported original parts, providing reliable quality assurance. These high-quality switches ensure consistent performance, reducing the risk of electrical failures and ensuring that the tool magazine operates smoothly under varying conditions. This commitment to using premium components underscores the magazine’s reliability, making it a trustworthy choice for critical machining applications.

Delving into its technical specifications, the Horizontal Disc Tool Magazine offers two pocket specifications to cater to different tool requirements: BT40/CAT40/DIN40/HSK63 and BT50/CAT50/DIN50/HSK100. The BT40/CAT40 variant provides tool capacities of 16T, 24T, or 32T, with a pocket pitch of 80mm. It supports a maximum tool diameter of 70mm when adjacent pockets are full and 150mm when empty, with a maximum tool weight of 8kg. This makes it suitable for precision machining tasks involving smaller to medium-sized tools, such as those found in mold-making or electronics manufacturing.

The larger BT50/CAT50 variant offers tool capacities of 24T, 30T, 32T, or 40T, with a pocket pitch of 127mm. It can handle a maximum tool diameter of 125mm (full adjacent pockets) or 240mm (empty) and a maximum tool weight of 15kg, making it ideal for heavier-duty applications in industries such as automotive or aerospace, where larger tools are commonly used.

Efficiency is a key strength of this tool magazine, with tool change times ranging from 1.1 to 2.9 seconds for the BT40/CAT40 model and 2.91 to 8.28 seconds for the BT50/CAT50 variant at 50Hz. Both models feature a magazine speed of 0.75 seconds per tool, ensuring rapid access to the required tool and minimizing idle time between machining operations. The tool change selection is powered by a roller gear cam, which guarantees smooth and precise movements, further enhancing the efficiency and reliability of the tool change process.

In summary, the Horizontal Disc Tool Magazine combines precision engineering, high-quality components, and efficient performance to meet the demands of modern machining. Its double roller cam mechanism, durable plastic holders, separate knife arm, and reliable electronic switches make it a versatile and trustworthy solution for a wide range of industrial applications. Whether in precision manufacturing or heavy-duty production, this tool magazine delivers the accuracy, reliability, and efficiency needed to optimize machining operations and stay ahead in today’s competitive market.