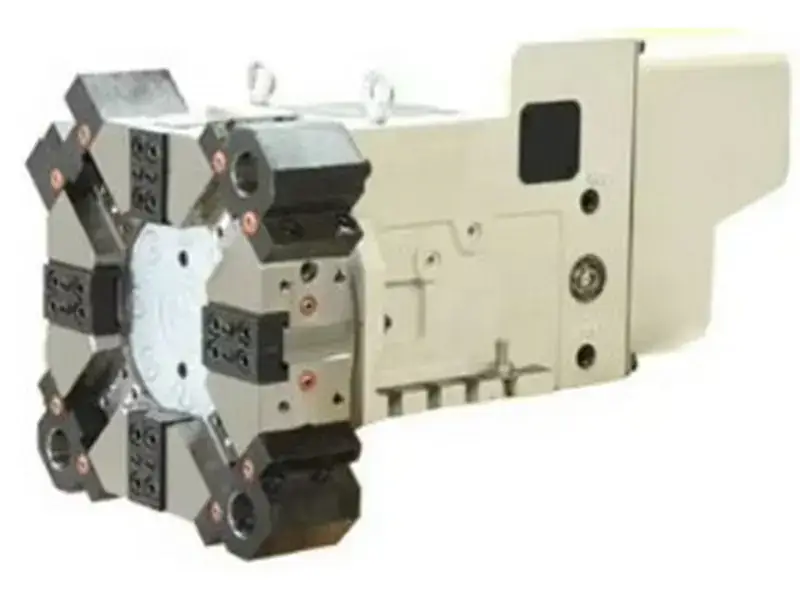

HAK38 Series Power Tooling NC Turret

Original price was: $23,000.00.$21,000.00Current price is: $21,000.00.

HAK38 Series Power Tooling NC Turret

| Item | Details |

|---|---|

| machinery test report | Provided |

| application | Turning Tool |

| video outgoing-inspection | Provided |

| standard | BT |

| core components | motor |

| weight (kg) | 55 |

| Center Height (mm) | 63/80/100/125 |

| Number of Tool Path | 08:12 |

| Power Tool Speed (rpm) | 6000/5000/4000/3500 |

| Clamping force (kg) | 1700/2600/3500/5200 |

| Hydraulic working pressure | 3.5±0.5 Mpa |

| Max. Power | 2.2/3.7/5.5/7.5kw |

| Indexing Accuracy | ±4 |

| Repeatability accuracy(“) | ±1.6 |

| Flow rate | 18/20/25/30 L/min |

| Inertia of movement for tooi-dis | 0.5/1.5/4/7 |

Description

HAK38 Series Power Tooling NC Turret

HAK38 Series Power Tooling NC Turret: Advanced Direct Drive Technology for Precision Machining

The HAK38 Series Power Tooling NC Turret represents a leap forward in machining technology, featuring a direct drive motor as its power source—an innovation that integrates the motor within the cutter head to directly drive the power tool holder. This design, combined with a water cooling system, ensures high precision, high speed, and low noise, making it an essential core accessory for high-grade CNC turning and milling centers, as well as composite machining centers. Capable of handling turning, milling, boring, tapping, and other complex part processes, the HAK38 Series redefines efficiency and reliability in modern manufacturing.

A standout feature of the HAK38 Series is its use of a direct drive motor, which is integrated into the disc, resulting in a compact and space-saving structure. Unlike traditional turrets with indirect transmission systems, this direct integration eliminates unnecessary components, reducing the overall size while enhancing structural rigidity. This compact design is particularly valuable in environments where workspace is limited, allowing for seamless integration into various machine tool configurations without compromising performance.

The direct drive mechanism is a game-changer for precision and speed. By having the motor output shaft directly drive the power holder, the HAK38 Series minimizes transmission clearance to an absolute minimum, enabling higher rotational speeds and more accurate tool positioning. Complementing this, the water cooling system efficiently reduces motor temperature, significantly improving overload capacity and increasing output torque. This thermal management ensures consistent performance even during prolonged high-intensity operations, meeting the stringent demands of CNC turning and milling centers for precision, speed, and low noise.

Durability and rigidity are ensured by a specially designed hydraulic locking structure. This system provides robust clamping force, keeping the turret stable during heavy cutting tasks and extending its service life. The hydraulic locking mechanism also contributes to the turret’s ability to maintain precision over time, even under repeated use, making it a reliable choice for high-volume production environments.

The direct drive mode offers long-term benefits, including a significantly extended service life compared to traditional turrets with gear-driven systems. By eliminating wear-prone transmission components, it achieves zero wear in critical areas, reduces maintenance costs, and ensures high reliability. This translates to less downtime for repairs and lower operational expenses, making the HAK38 Series a cost-effective investment for manufacturers.

Delving into the technical parameters, the HAK38 Series includes three models tailored to different machining needs. The HAK38070-BMT45 features a center height of 70mm, 12 stations, and operates at a hydraulic pressure of 2 Mpa. It delivers a maximum cutting torque of 10 N.m, boasts a repeatability accuracy of ±2″, and achieves a tool change time of 0.3 seconds, with the power motor reaching a maximum speed of 8000 rpm.

The HAK38080-BMT55 steps up with an 80mm center height, 12 stations, and a hydraulic pressure of 2.5 Mpa. It offers a higher maximum cutting torque of 20 N.m, maintaining the same repeatability accuracy of ±2″ while requiring 0.4 seconds for tool changes, with the motor also reaching 8000 rpm.

For more demanding applications, the HAK38100-BMT65 provides a 100mm center height, 12 stations, and a hydraulic pressure of 3 Mpa. It delivers a maximum cutting torque of 30 N.m, retains the ±2″ repeatability accuracy, and has a tool change time of 0.5 seconds, with the motor speed remaining at 8000 rpm.

These parameters highlight the HAK38 Series’ ability to scale with machining requirements, from lighter precision tasks to heavier cutting operations, all while maintaining exceptional speed and accuracy. The consistent motor speed of 8000 rpm across all models ensures efficient material removal, while the rapid tool change times minimize downtime between operations.

In summary, the HAK38 Series Power Tooling NC Turret sets a new standard for performance in CNC machining. Its direct drive technology, water cooling system, robust hydraulic locking, and durable design make it a versatile and reliable solution for high-grade turning and milling centers. Whether handling complex part processes or high-volume production, the HAK38 Series delivers the precision, speed, and efficiency needed to excel in today’s competitive manufacturing landscape.