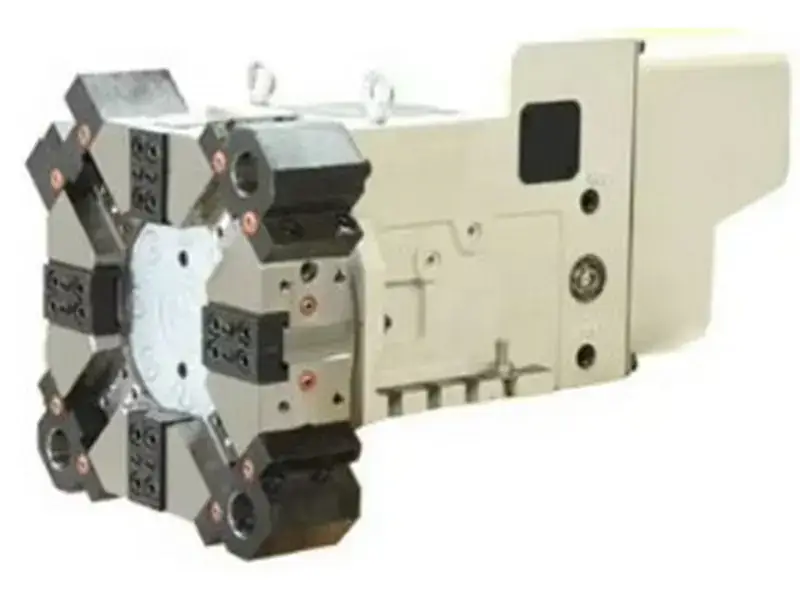

D Series Axial Servo Power Tooling Turret

Original price was: $42,000.00.$41,000.00Current price is: $41,000.00.

D Series Axial Servo Power Tooling Turret

| Item | Details |

|---|---|

| machinery test report | Provided |

| application | Turning Tool |

| video outgoing-inspection | Provided |

| standard | Other |

| core components | motor |

| weight (kg) | 180 |

| Center Height (mm) | 63/80/100/125 |

| Number of Tool Path | 08:12 |

| Power Tool Speed (rpm) | 6000/5000/4000/3500 |

| Clamping force (kg) | 1700/2600/3500/5200 |

| Hydraulic working pressure | 3.5±0.5 Mpa |

| Max. Power | 2.2/3.7/5.5/7.5kw |

| Indexing Accuracy | ±4 |

| Repeatability accuracy(“) | ±1.6 |

| Flow rate | 18/20/25/30 L/min |

| Inertia of movement for tooi-dis | 0.5/1.5/4/7 |

Description

D Series Axial Servo Power Tooling Turret

D Series Axial Servo Power Tooling Turret: Precision and Versatility in Machining

The D Series Axial Servo Power Tooling Turret is a sophisticated machining solution built on the foundation of the D series servo turret, enhanced by an external power module to form the SLTA axial power tooling servo system. This integration results in a reasonably compact layout, making it an ideal choice for CNC lathes and turning centers that require high precision and versatility in handling complex machining tasks. Designed to excel in industries such as automotive, aerospace, and precision engineering, the D Series delivers reliable performance across a range of applications, from simple turning to intricate milling and drilling operations.

A key feature of the D Series is its use of a high-precision triple Hirth coupling combined with hydraulic clamping devices for the power head’s loosening and combining actions. This setup ensures exceptional indexing accuracy and reliable clamping, critical factors for maintaining consistent machining quality. The Hirth coupling, with its fine-toothed design, guarantees precise angular positioning, minimizing errors during tool changes. The hydraulic clamping system provides robust holding force, keeping tools securely in place even during heavy cutting operations, thus enhancing stability and reducing vibrations that could compromise precision.

The D Series is equipped with a separate spindle servo motor under simple control, which supplies the driving force for the tools. This motor features a modular interface that can adapt to a variety of spindle motors, with a maximum power output of up to 11kw. This flexibility allows manufacturers to select the motor that best suits their specific machining needs, ensuring optimal performance across different materials and operation types. Whether dealing with soft metals or hardened alloys, the adjustable power output ensures efficient material removal without sacrificing precision.

Each station in the D Series turret can be fitted with a power tool, but driving force is only provided to the active workstation. This design optimizes energy usage and reduces unnecessary wear on components, extending the turret’s service life. The tool block complies with international standards DIN69880 and DIN1809, ensuring compatibility with a wide range of industry-standard tools. This adherence to global standards simplifies tool selection and replacement, making the turret a versatile addition to any machining setup.

Delving into the technical parameters, the D Series includes four models—D63A, D80A, D100A, and D125A—with center heights of 63mm, 80mm, 100mm, and 125mm respectively, catering to different workpiece sizes. Each model offers 8 or 12 workstations, providing ample capacity for diverse tool inventories. The power tool speed varies across models, from 6000 rpm for the D63A to 3500 rpm for the D125A, allowing for efficient machining across different material thicknesses and hardness levels.

In terms of speed, the rotating time (including locking) for adjacent tool positions ranges from 0.9 seconds for the D63A to 1.8 seconds for the D125A. For the farthest tool positions (180° rotation including locking), the time ranges from 1.2 seconds to 2.5 seconds, ensuring rapid tool changes and minimal downtime. The clamping force is impressive, starting at 1700kg for the D63A and reaching 5200kg for the D125A, highlighting the turret’s ability to handle heavy cutting forces.

The hydraulic working pressure is consistent across all models at 3.5±0.5MPa, with flow rates ranging from 18 to 30 L/min, ensuring reliable power delivery. The maximum carrying inertia ranges from 0.5 kgm² to 7 kgm², and the maximum unbalanced torque from 10 Nm to 60 Nm, demonstrating the turret’s stability even with larger tools.

Precision is guaranteed with an indexing accuracy of ±4″ and a repeatability accuracy of ±1.6″ across all models. The power tool holder sizes range from φ20mm for the D63A to φ50mm for the D125A, accommodating various tool dimensions. The maximum power of the drive motor (S3-40%-10min) ranges from 2.2kw to 7.5kw, with a motor-to-tool transmission ratio of 1:1, ensuring efficient power transfer.

The weight of the turret (excluding the power motor) ranges from 95kg to 350kg, balancing structural stability with ease of integration. With its robust design, high precision, and versatile features, the D Series Axial Servo Power Tooling Turret is a reliable solution for modern machining needs, delivering consistent performance and efficiency in high-demand manufacturing environments.