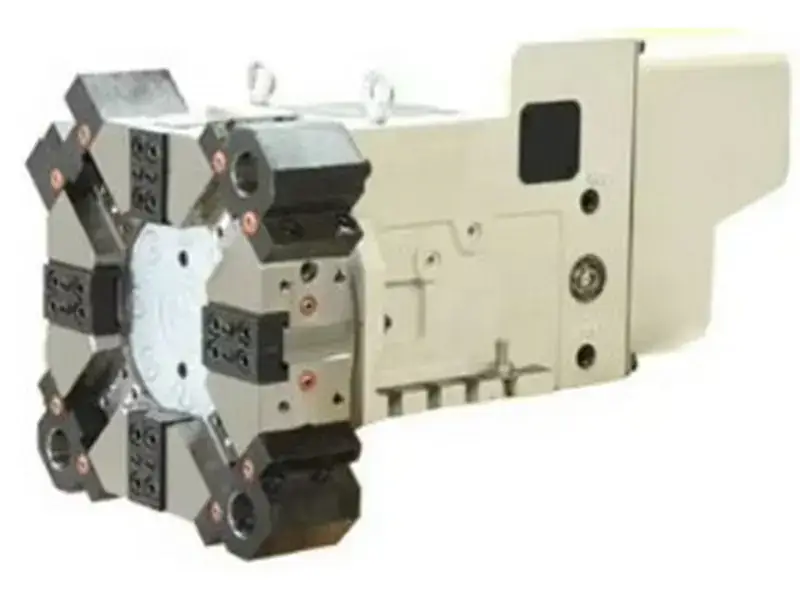

CLT Series 8/12 Station Vertical NC Turret

Original price was: $4,700.00.$4,600.00Current price is: $4,600.00.

CLT Series 8/12 Station Vertical NC Turret

| Item | Details |

|---|---|

| machinery test report | Provided |

| application | Turning Tool |

| video outgoing-inspection | Provided |

| standard | Other |

| core components | motor |

| weight (kg) | 90 |

| Center Height (mm) | 63/80/80/100 |

| Number of Tool Path | 08:12 |

| Max. Tangential Torque (KN.m) | 1.5/2/2.5/3.5 |

| working pressure(mpa) | 3.5 |

| working flow rate L/min | 18/22/25/30 |

| The Max Axial Torque | 1500/2000/2500/3500 N.M |

| Indexing Accuracy | ±4 |

| Repeatability accuracy(“) | ±1.6 |

| Flow rate | 18/20/25/30 L/min |

| Max unbalance moment of torque | 15/20/25/50 Nm |

Description

CLT Series 8/12 Station Vertical NC Turret

CLT Series Cam Hydraulic Turret: Precision and Power for Advanced Machining

In the realm of high-precision machining, where speed, accuracy, and reliability are paramount, the CLT Series Cam Hydraulic Turret emerges as a cutting-edge solution designed to elevate the performance of CNC lathes and turning centers. This advanced turret system integrates innovative cam technology with hydraulic power, delivering exceptional indexing accuracy, rapid tool changes, and robust performance—making it an ideal choice for industries such as automotive, aerospace, and precision engineering.

At the core of the CLT Series’ excellence is its internal cam mechanism, which ensures high indexing accuracy and fast tool changes. Unlike traditional turrets that rely on less precise mechanisms, the cam-driven design guarantees consistent positioning, minimizing errors and enhancing the overall precision of machining operations. This feature is particularly critical for applications requiring tight tolerances, such as the production of complex automotive components or aerospace parts, where even minor deviations can compromise functionality.

Driven by a hydraulic motor, the CLT Series delivers high torque output and stable tool changes. This hydraulic drive system provides the power needed to handle heavy-duty machining tasks, ensuring smooth and reliable operation even under intense cutting conditions. The combination of hydraulic power and cam precision results in a turret that can transition between tools quickly and seamlessly, reducing idle time and boosting productivity in high-volume production environments.

The tool release and clamping mechanism of the CLT Series also employs hydraulic technology, offering reliable action that is well-suited for heavy cutting operations. This robust clamping system ensures that tools remain securely in place during aggressive machining, minimizing vibrations and enhancing cutting stability. Whether working with hard metals or thick workpieces, the hydraulic clamping mechanism provides the strength and consistency needed to maintain precision, even during prolonged use.

Control is another area where the CLT Series excels, utilizing a proximity detector and PLC programming to enable smart selection of nearby tools. This intelligent control system optimizes tool change sequences by prioritizing access to tools positioned closest to the current working position, reducing unnecessary rotation and further minimizing cycle times. The integration of PLC programming also allows for easy customization of tool change logic, adapting to specific machining requirements and enhancing workflow efficiency.

The CLT Series offers additional versatility with customizable high-pressure cooling options, including 30BAR, 50BAR, and 70BAR configurations. This flexibility ensures effective coolant delivery to the cutting zone, even in demanding applications, reducing heat buildup, extending tool life, and improving surface finish quality. Whether machining heat-sensitive materials or performing high-speed cutting, the adjustable cooling system contributes to consistent performance and reduced tool wear.

Delving into its technical specifications, the CLT Series provides a range of options to suit diverse machining needs. The center height is available in 63mm, 80mm, 80mm, and 100mm variants, while the allowed number of tools is 8 or 12 positions, offering flexibility for both simple and complex machining tasks. The working flow rate ranges from 18L/min to 30L/min, ensuring adequate hydraulic power for various operational demands.

In terms of speed, the turret demonstrates impressive performance: rotating 45° takes just 0.35 to 0.65 seconds, with rotation and locking completed in 0.45 to 0.8 seconds. For 180° rotation, the time ranges from 1.5 to 1.8 seconds, with rotation and locking taking 1.6 to 1.95 seconds—speeds that significantly reduce downtime between tool changes. The maximum unbalance moment of torque ranges from 15Nm to 50Nm, while the maximum tangential and axial moments of torque reach up to 3500Nm, highlighting its capability to handle heavy cutting forces.

Precision is guaranteed with a repeatability accuracy of ±1.6″ and an indexing accuracy of ±4″, ensuring consistent results across multiple machining cycles. The net weight, excluding the tool disc, ranges from 35kg to 100kg, with a working pressure of 3.5MPa, balancing structural stability with operational efficiency.

In summary, the CLT Series Cam Hydraulic Turret represents a perfect fusion of precision, power, and intelligence. Its cam-driven mechanism, hydraulic power, smart control system, and customizable features make it a versatile and reliable solution for modern machining challenges. Whether in high-volume production or custom manufacturing, the CLT Series delivers the speed, accuracy, and durability needed to optimize performance and stay competitive in today’s manufacturing landscape.