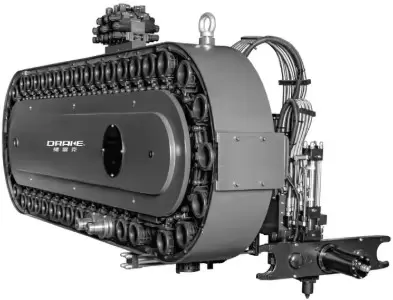

Chain Plate Hydraulic Swing Arm Tool Magazine

$0.00

Chain Plate Hydraulic Swing Arm Tool Magazine

| Item | Details |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| weight (kg) | 25 |

| Tool capacity | 40T / 60T |

| Tool change time | 3(ATC) |

| Max. tool weight | 25kg |

| Max. tool diameter | 125/250 |

| After-sale Service | Online Support |

| Magazine speed | 0.85 |

| Tool management mode | random |

| Tool Change Selection | Hydraulic Rock and Gear Mechanism |

| Pocket Spec | BT50/CAT50/DIN50/HSK100 |

Description

Chain Plate Hydraulic Swing Arm Tool Magazine

Chain Plate Hydraulic Swing Arm Tool Magazine: Reliable Performance for Heavy-Duty Machining

In the realm of industrial machining, where efficiency and reliability are paramount, the Chain Plate Hydraulic Swing Arm Tool Magazine stands out as a high-performance solution tailored to meet the demands of heavy-duty operations. This advanced tool storage and changing system integrates robust design with precision engineering, making it an essential component for CNC machining centers in sectors such as aerospace, automotive, and heavy machinery manufacturing.

A key highlight of this tool magazine is its hydraulic rack-type tool changer, specifically engineered to handle heavy and long knives with exceptional stability. Unlike conventional systems that may falter under the weight or length of large tools, this design ensures secure gripping and smooth movement throughout the tool change process. This capability is crucial for industries that regularly work with large-diameter cutters or elongated tools, as it minimizes the risk of tool damage and operational disruptions, thereby maintaining consistent production flow.

The Chain Plate Hydraulic Swing Arm Tool Magazine boasts a strong structure that delivers high stability even during prolonged and intensive use. Constructed to withstand the rigors of industrial environments, it effectively reduces vibrations and ensures consistent performance, whether during rapid tool changes or extended machining runs. This structural integrity not only enhances the accuracy of machining operations but also reduces downtime by minimizing wear and tear, making it a reliable choice for high-volume production facilities.

Flexibility is another defining feature of this tool magazine, as it offers non-standard customization options to adapt to the specific shape and requirements of different machine tools. This adaptability allows for seamless integration into various CNC setups, eliminating compatibility issues and enabling manufacturers to optimize their workflow based on space constraints, production demands, or unique operational needs. Such customization ensures that the tool magazine aligns perfectly with the machine tool, enhancing overall efficiency and productivity.

Delving into its technical specifications, the Chain Plate Hydraulic Swing Arm Tool Magazine is designed to accommodate BT50/CAT50/DIN50/HSK100 pocket specifications, ensuring compatibility with a wide range of heavy-duty tools commonly used in industrial machining. It offers tool capacities of 40T and 60T, providing flexibility to handle both moderate and high-volume production runs. This range allows manufacturers to scale their operations without compromising on tool storage efficiency, making it suitable for diverse production environments.

In terms of tool dimensions, the magazine supports a maximum tool diameter of 125mm when adjacent pockets are full and 250mm when empty, with a maximum tool weight of 25kg. These specifications highlight its ability to manage large and heavy tools, making it ideal for heavy-duty machining tasks that require substantial cutting power. Whether working with thick metal workpieces or complex components, this tool magazine ensures that the right tool is always available and securely handled.

Efficiency is a hallmark of this system, with a tool change time of just 3 seconds (ATC) at 50Hz, ensuring minimal idle time between machining operations. The magazine speed is 0.85 seconds per tool, enabling rapid access to the required tool and keeping production workflows moving smoothly. This combination of speed and precision significantly boosts overall productivity, allowing manufacturers to meet tight deadlines without sacrificing quality.

The tool management mode employs a random selection system, enabling operators to access any tool in the magazine without sequential ordering. This feature streamlines workflow by reducing setup times and ensuring that the right tool is available exactly when needed. The tool change process is powered by a hydraulic rack and gear mechanism, which guarantees smooth, precise, and repeatable movements. This mechanism enhances operational consistency, reduces the margin for error, and ensures that each tool change is executed with the utmost reliability.

In summary, the Chain Plate Hydraulic Swing Arm Tool Magazine is a versatile and robust solution that excels in handling heavy tools, adapting to custom configurations, and delivering efficient performance. Its combination of strength, flexibility, and speed makes it an invaluable asset for manufacturers seeking to optimize productivity and precision in their machining operations. Whether in high-volume production facilities or custom manufacturing shops, this tool magazine proves to be a reliable partner in meeting the challenges of modern industrial machining.