BMT Series 90 Degree Driven Tool Holder

Original price was: $1,000.00.$900.00Current price is: $900.00.

BMT Series 90 Degree Driven Tool Holder

| Item | Details |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| weight (kg) | 3 |

| Model | BMT45-90-60-ER25 |

| Products name | BMT Series 0 Degree Driven Tool Holder |

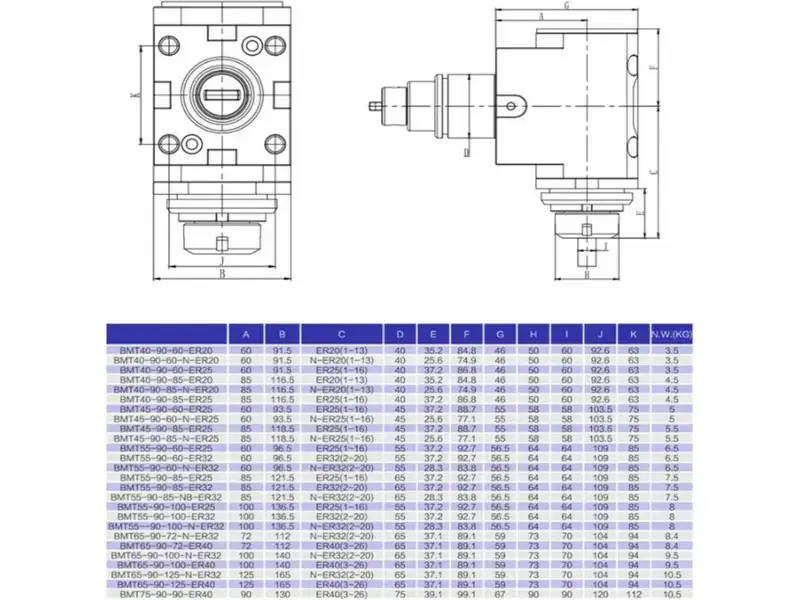

| Tool Holder Sizes: | BMT40/BMT45/BMT55/BMT65 |

| Collet locking method | External locking |

| Type | Power Tool Parts |

| Usage | Cnc Milling Machine Lathe |

| Material | cast iron |

| Advantage | Accurate Positioning |

Description

BMT Series 90 Degree Driven Tool Holder

BMT Series 90 Degree Driven Tool Holder: Enhanced Rigidity for Angular Machining

The BMT Series 90 Degree Driven Tool Holder is a specialized and high-performance accessory designed to expand the capabilities of CNC lathes, focusing on precision angular machining tasks. With its robust construction, adherence to international standards, and compatibility with leading machine brands, this tool holder is an essential asset for manufacturers requiring accurate and efficient processing of perpendicular surfaces, cross holes, and angular features.

A defining characteristic of the BMT Series 90 Degree Driven Tool Holder is its strict compliance with global standards, ensuring seamless integration and reliable performance. Its joint faces are manufactured in accordance with DIN 1809, a specification that guarantees uniform dimensions and precise fitting, enabling easy installation and interchangeability across various CNC lathe turrets. This standardization minimizes setup time and ensures consistent performance, whether used in small-scale workshops or large production facilities. Additionally, the output shaft collet conforms to DIN 6499, facilitating compatibility with a wide range of standard tools and enhancing versatility in tool selection.

Compatibility with prominent CNC lathe brands is a key advantage of this tool holder. It is specifically engineered to work with DOOSAN, DAEWOO, and HWACHON machines, among others, making it a practical choice for facilities utilizing these popular models. This compatibility eliminates the need for custom modifications, reducing costs and simplifying the integration process, whether retrofitting existing equipment or equipping new systems.

In terms of tooling flexibility, the BMT Series 90 Degree Driven Tool Holder utilizes standard ER collets, including ER20, ER25, ER32, ER40, and ER50. These widely available collets are compatible with a diverse range of cutting tools, from drills and taps to end mills, simplifying tool changes and reducing inventory costs. Manufacturers can leverage their existing stock of ER collets, minimizing the need for specialized tooling and streamlining operational workflows.

The tool holder offers two locking methods: external lock and internal lock. The internal locking type provides distinct benefits, including more stable tool clamping and higher precision, which is particularly valuable for high-speed or heavy-duty machining operations. This enhanced stability prevents tool slippage, ensuring consistent performance and reducing the risk of errors. The external lock, meanwhile, offers simplicity and ease of use, making it suitable for less demanding applications. This flexibility allows manufacturers to select the locking method that best aligns with their specific machining requirements.

Performance is a standout feature of the BMT Series 90 Degree Driven Tool Holder, with a maximum rotational speed of up to 6000 RPM for wet cutting and 4000 RPM for dry cutting. This range of speeds enables efficient material removal across various machining scenarios, from high-speed finishing to more controlled dry cutting operations. The ability to handle both wet and dry cutting expands its application scope, making it suitable for diverse materials and processes.

A key enhancement in this tool holder is the adoption of imported tapered bearings, which significantly increase rigidity. These bearings provide superior support, minimizing deflection during heavy cutting and ensuring precise tool positioning even under high loads. The increased rigidity is particularly beneficial for machining hard materials or performing deep cuts, where stability is critical to achieving accurate dimensions and smooth surface finishes. Additionally, the tapered bearings contribute to reduced vibration and noise, enhancing overall operational efficiency and extending the tool holder’s service life.

The 90-degree design of the tool holder makes it ideal for a range of angular machining tasks, including milling perpendicular surfaces, drilling cross holes, and creating angular features. Its precise positioning ensures that tools are held at a strict right angle to the workpiece, enabling consistent and accurate results in applications such as face milling, slotting, and chamfering. This capability is invaluable for industries such as automotive, aerospace, and precision engineering, where complex components with perpendicular features are common.

In summary, the BMT Series 90 Degree Driven Tool Holder combines adherence to international standards, compatibility with leading machine brands, tooling flexibility, and enhanced rigidity to deliver exceptional performance in angular machining tasks. Its high rotational speeds, reliable locking mechanisms, and robust bearing system make it a versatile and reliable accessory for modern CNC lathes. Whether engaged in high-speed wet cutting or controlled dry cutting, this tool holder provides the precision, stability, and efficiency needed to meet the demands of today’s competitive manufacturing landscape.