40T/60T Automatic Tool Changer Tool Magazine

Original price was: $11,000.00.$10,000.00Current price is: $10,000.00.

40T/60T Automatic Tool Changer Tool Magazine

| Item | Details |

|---|---|

| video outgoing-inspection | Provided |

| machinery test report | Provided |

| weight (kg) | 15 |

| Tool capacity | 16T / 20T |

| Tool change time | 1.3sec / 50hz |

| Max. tool weight | 8kg |

| Max. tool diameter( full loaded) | 75/150mm |

| After-sale Service | Online Support |

| Magazine Speed | 0.25 |

| Tool magazine mode | random |

Description

40T/60T Automatic Tool Changer Tool Magazine

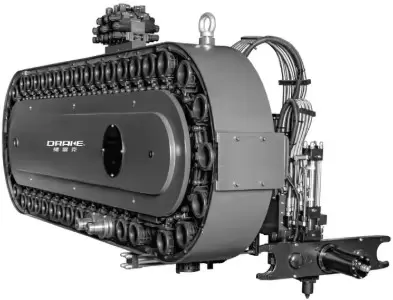

Radial Disc Tool Magazine: Efficient and Adaptable for Modern Machining

In the fast-paced world of modern manufacturing, where efficiency and adaptability are key to staying competitive, the Radial Disc Tool Magazine stands out as a high-performance solution designed to enhance the capabilities of CNC machining centers. This innovative tool storage and changing system combines robust engineering with smart design, making it an ideal choice for industries that require reliable handling of tools and seamless integration into diverse production setups.

A key feature of the Radial Disc Tool Magazine is its disc-type hydraulic translation mechanism, which enables it to hold heavy and long knives with exceptional stability. This design ensures that even larger or bulkier tools are securely gripped and smoothly maneuvered during the tool change process, minimizing the risk of damage or operational disruptions. This capability is particularly valuable in sectors such as automotive parts manufacturing, mold-making, and precision engineering, where a variety of tool sizes and weights are used to achieve complex machining tasks.

The radial disc tool magazine boasts a strong structure that delivers high stability, even during prolonged and intensive use. Constructed to withstand the rigors of industrial environments, it effectively reduces vibrations and maintains consistent performance, whether during rapid tool changes or extended production runs. This structural integrity not only enhances the accuracy of machining operations but also extends the service life of the system, reducing maintenance costs and downtime—critical factors for maximizing productivity in high-volume manufacturing facilities.

Flexibility is another standout attribute of this tool magazine, as it offers non-standard customization options to adapt to the specific shape and requirements of different machine tools. This adaptability allows for seamless integration into various CNC setups, eliminating compatibility issues and enabling manufacturers to optimize their workflow based on space constraints, production demands, or unique operational needs. Whether modifying the layout to fit a compact workshop or adjusting the configuration for a specific machining process, the radial disc tool magazine can be tailored to meet exact specifications, enhancing overall efficiency.

Delving into its technical specifications, the Radial Disc Tool Magazine is designed to accommodate the BT40/CAT40/DIN40/HSK63 pocket specifications, ensuring compatibility with a wide range of standard tools commonly used in precision machining. It offers versatile tool capacities of 40T and 60T, providing ample storage for both medium and high-volume production runs. This range allows manufacturers to handle complex machining tasks that require frequent tool changes without compromising on efficiency.

In terms of tool dimensions, the magazine supports a maximum tool diameter of 75mm when adjacent pockets are full and 150mm when empty, with a maximum tool weight of 8kg. These specifications make it well-suited for handling a variety of tools, from small precision cutters to larger end mills, ensuring that it can adapt to the diverse needs of modern machining operations.

Efficiency is a defining trait of the Radial Disc Tool Magazine, with a tool change time of just 1.3 seconds at 50Hz. This rapid turnaround minimizes idle time between machining operations, keeping production workflows moving smoothly and boosting overall productivity. The magazine speed is equally impressive at 0.25 seconds per tool, enabling quick access to the required tool and ensuring that the right tool is always available when needed. This combination of speed and precision significantly reduces cycle times, allowing manufacturers to meet tight deadlines and increase output.

The tool management mode employs a random selection system, which enables operators to access any tool in the magazine without sequential ordering. This feature streamlines workflow by reducing setup times and ensuring that tools can be accessed in the most efficient sequence for the task at hand. The tool change process is powered by a roller gear cam, which guarantees smooth, precise, and repeatable movements. This mechanism enhances operational consistency, reduces the margin for error, and ensures that each tool change is executed with the utmost reliability.

In summary, the Radial Disc Tool Magazine is a versatile and efficient solution that excels in handling a range of tools, adapting to custom configurations, and delivering rapid performance. Its combination of strong structure, hydraulic translation mechanism, and high-speed operation makes it an invaluable asset for manufacturers seeking to optimize productivity and precision in their machining operations. Whether in high-volume production facilities or specialized workshops, this tool magazine proves to be a reliable partner in meeting the challenges of modern industrial machining.