VDI DIN 69880 ツールホルダー タレット B1 B2 C1 C2 VDI30 40 50

元価格は$240.00。$220.00現在の価格は$220.00。

VDI DIN 69880 ツールホルダー タレット B1 B2 C1 C2 VDI30 40 50

| 項目 | 詳細 |

|---|---|

| マシンタイプ | パンチングマシン、フライス盤、旋盤、研削盤、ボール盤、ターニングマシン、シェーピングマシン、プランニングマシン |

| ビデオ出荷検査 | 提供 |

| 機械試験報告書 | 提供 |

| 重量(kg) | 3.5 |

| 使用方法 | CNCフライス盤旋盤 |

| 申し込み | CNCマシンタレット |

| タイプ | スタンダード |

| 素材 | 鋳鉄 |

| モデル | 標準モデル |

| メリット | 正確なポジショニング |

| 精密 | 高精度・高性能 |

説明

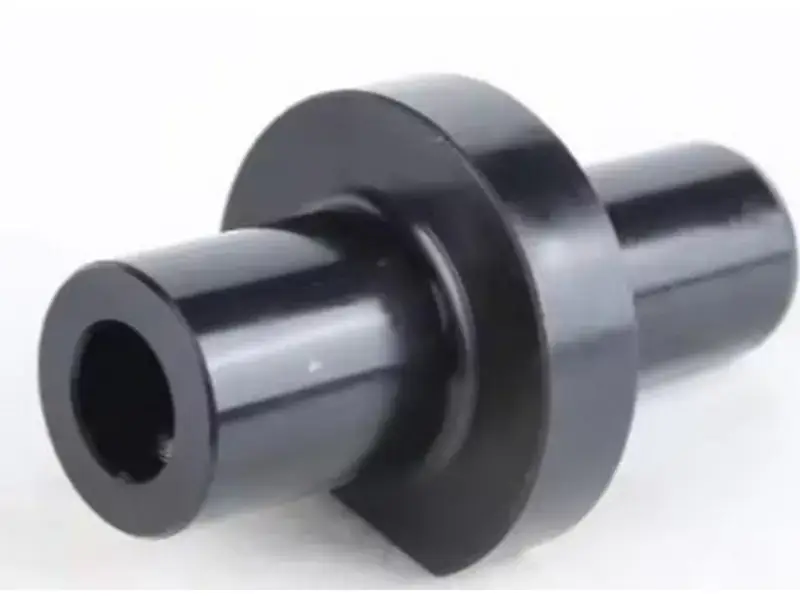

VDI DIN 69880 ツールホルダー タレット B1 B2 C1 C2 VDI30 40 50

NCツールホルダーシリーズ VDI DIN 69880:CNC旋盤タレット用汎用ソリューション

NCツールホルダシリーズVDI DIN 69880は、CNC旋盤刃物台の性能を向上させるために設計された、精密設計の包括的なツールホルダシリーズです。モデルB1、B2、C1、C2を含み、VDI30、40、50仕様に対応するこのシリーズは、国際規格への厳格な準拠と汎用的な機能を兼ね備えており、一般的なエンジニアリングから高精度の航空宇宙製造まで、多様な加工アプリケーションに不可欠な資産となっています。

このシリーズの核心は、DIN 69880規格に準拠していることで、すべてのバリエーションで均一な寸法、機能、互換性を保証しています。この標準化により、対応するサイズのVDI刃物台(VDI30、40、50)とのシームレスな統合が可能になり、互換性のハードルがなくなり、製造業者のセットアップ時間が短縮されます。このシリーズは、小型CNC旋盤に装備する場合でも、大規模な生産センターに装備する場合でも、一貫した性能を保証します。

IT6(h6)公差で加工された円筒形シャンクから始まるNCツールホルダーシリーズの特徴は、精密さです。この厳密な基準により、タレット内でしっかりと固定され、ラジアル方向の遊びが最小限に抑えられ、高速回転時の安定性が向上します。振動の低減は、仕上げ面の品質を向上させるだけでなく、特に医療部品や自動車の精密部品など、公差が厳しく要求される材料を加工する場合に、工具とワークの両方を潜在的な損傷から保護します。

フルケース焼入れにより、すべてのツールホルダーに耐久性が設計されています。このプロセスにより、機械的応力を吸収する1000N/mm²を超える強度を持つ強靭なコアを保持しながら、卓越した耐摩耗性を持つ硬化外層(表面硬度58±2HRC)が形成されます。このバランスにより、過酷な切削作業にも耐えうる強靭なホルダーとなり、耐用年数の延長と交換頻度の低減が可能となります。

シャフト、セレーション、座面、位置決めボア、クランププレート、ロケーターボアなどの主要部品は、精密研削が施されます。この入念な工程により、平坦度、平行度、寸法精度が保証され、一貫した工具の位置決めを維持するために重要です。その結果、複数のセットアップで再現性のある性能を発揮し、バッチ生産で均一な部品品質を確保し、頻繁な再校正の必要性を低減します。

多様な加工ニーズに合わせた調整機能により、汎用性が向上。各ホルダは、次の低いカッタ高さまで素早く調整でき、専用工具を使用せずに変化するワーク要件に対応します。さらに、2つのストップスクリューでカッターの位置を微調整できるため、フェーシング、溝入れ、ねじ切りなどの加工に不可欠な切削深さと高さを正確に制御できます。この適応性により、このシリーズは単純な加工にも複雑な加工にも適しており、複数の専用ホルダーを必要としません。

クランプ機構は、バネを取り付けたプレッシャープレートを備え、安定した力でカッターを固定し、高トルクや振動下でもスリップを防止します。この信頼性の高いグリップにより、切削安定性が向上し、早期摩耗を最小限に抑えることで工具寿命が延び、加工中にコストのかかるエラーが発生するリスクが低減します。

効率的なクーラント供給は、内部ボールノズルによって達成され、新しいクランプ固定具を使用して素早く調整することができます。切削領域への最適なクーラントフローは、熱の蓄積を低減し、切り屑を洗い流し、工具寿命を延ばします。これは、高速加工や、チタンやインコネルなどの熱に敏感な材料を扱う場合に特に有効です。

DIN 69880で規定されているように、各ホルダーには、オプションのシールリングを装着できるように、シャンクのシール面にアンダーカットが施されています。この機能により、クーラントの漏れを防ぎ、タレット内部を汚染から保護し、システム全体の信頼性を高め、メンテナンスのダウンタイムを短縮します。

要約すると、B1、B2、C1、C2モデルおよびVDI30、40、50タイプを含むNCツールホルダーシリーズVDI DIN 69880は、最新のCNC旋盤に精度、耐久性、汎用性を提供します。規格への準拠、堅牢な構造、適応性の高い設計により、多様な産業用途において一貫した性能、ダウンタイムの削減、高品質な結果を求める製造業者にとって、信頼できる選択肢となっています。