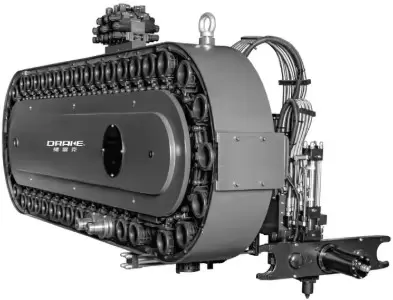

チェーン式縦型・横型ツールマガジン

元価格は$18,000.00。$17,000.00現在の価格は$17,000.00。

チェーン式縦型・横型ツールマガジン

| 項目 | 詳細 |

|---|---|

| マシンタイプ | パンチングマシン、フライス盤、旋盤、研削盤、ボール盤、ターニングマシン、シェーピングマシン、プランニングマシン |

| ビデオ出荷検査 | 提供 |

| 機械試験報告書 | 提供 |

| 重量(kg) | 300 |

| 工具容量 | 40T/ 48T/ 60T |

| 工具最大長 | 300mm |

| 最大工具重量 | 8kg |

| 工具最大径(全負荷時) | 80mm |

| 工具最大径(隣接なし) | 150mm |

| 最大工具径(隣接ポケットフル時 | 75/127 |

| 工具交換の選択 | 油圧ロックとギア機構 |

| ツール管理モード | ランダム |

| メリット | 正確なポジショニング |

説明

チェーン式縦型・横型ツールマガジン

現代の機械加工の領域では、効率性、汎用性、信頼性が最も重要であり、チェーン式垂直・水平ツールマガジンは、これらの要求を満たすために設計された重要なコンポーネントとして際立っています。この先進的な工具収納・交換システムは、CNC工作機械の生産性を高めるように設計されており、多様な産業用途に対応する強度、適応性、精度のシームレスな融合を提供します。

このツールマガジンの特徴は、重くて長い工具の取り扱いに優れた油圧ラック式ツールチェンジャーにあります。大型工具や重量のある工具の取り扱いに苦慮する従来のシステムとは異なり、この設計は安定した確実な取り扱いを保証し、工具の損傷や作業中断のリスクを低減します。このため、航空宇宙、自動車、重機械製造など、加工作業にかさばる工具や細長い工具が使用されることが多い業界にとって、理想的な選択肢となります。

チェーンタイプの垂直・水平ツールマガジンは、運転中に高い安定性を実現する強固な構造を誇ります。振動を最小限に抑え、工具の交換や長時間の使用でも安定した性能を発揮します。立形マシニングセンタや横形ボーリングミルに組み込んでも、マガジンの堅牢な構造が信頼性の高い運転を保証し、加工精度の向上とダウンタイムの短縮に貢献します。

もう一つの重要な利点は、工作機械の形状や特定の要件に応じてカスタマイズできる非標準的な適応性です。この柔軟性により、ツールマガジンは幅広い機械構成にシームレスに統合でき、互換性の問題を排除し、ワークフロー効率を最適化します。メーカーは、スペースの制約のためにレイアウトを変更したり、大量加工用に容量を調整したりするなど、独自の生産ニーズに合わせてシステムをカスタマイズすることができます。

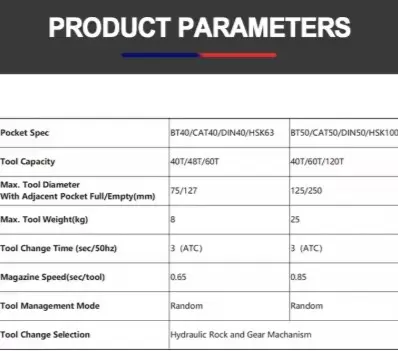

ツールマガジンの仕様については、異なる工具規格に対応するため、2つの主要なポケット仕様が用意されている:BT40/CAT40/DIN40/HSK63とBT50/CAT50/DIN50/HSK100です。BT40/CAT40は40T、48T、60Tの工具容量を提供し、BT50/CAT50オプションは40T、60T、120Tの工具容量を提供し、小規模な精密作業と大規模な生産ランの両方に適している。

工具寸法に関しては、BT40/CAT40モデルは、隣接するポケットが満杯の場合、最大工具径75mm、空の場合127mm、最大工具重量8kgに対応する。より大型のBT50/CAT50は、これらの能力を拡張し、最大工具径125mm(隣接するポケットが満杯)または250mm(空)、最大工具重量25kgに対応し、ヘビーデューティー用途への適性をさらに強調している。

効率性はこのシステムの特徴であり、両仕様とも工具交換時間は50Hzでわずか3秒(ATC)で、アイドル時間を最小限に抑え、全体的な生産性を高める迅速なターンアラウンドを実現します。マガジンの速度も同様に素晴らしく、BT40/CAT40モデルは工具1本あたり0.65秒、BT50/CAT50モデルは工具1本あたり0.85秒で動作し、必要な工具に素早くアクセスできるため、加工を中断することがありません。

工具管理モードは、ランダム選択システムを採用しており、オペレータは、順次順序付けすることなく、マガジン内のどの工具にもアクセスすることができ、ワークフローを合理化し、セットアップ時間を短縮します。工具交換の選択は、油圧ラックとギア機構によって行われ、スムーズで正確、再現性のある工具交換を保証し、操作の一貫性を高め、エラーの余地を減らします。

要約すると、チェーン式縦型・横型ツールマガジンは、CNCマシニングセンタの性能を向上させる汎用性の高い堅牢なソリューションです。重量のある工具を扱い、非標準的な構成に適応し、迅速で安定したオペレーションを実現するその能力は、生産性と精度の最適化を求めるメーカーにとって、かけがえのない資産となります。大量生産であれ、カスタム加工であれ、このツールマガジンは、現代の製造業の課題に対応する信頼できるパートナーです。