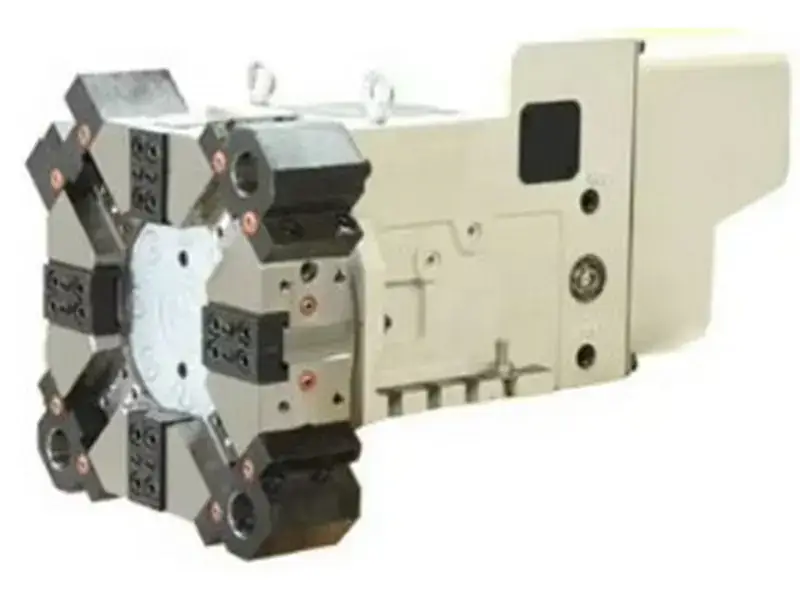

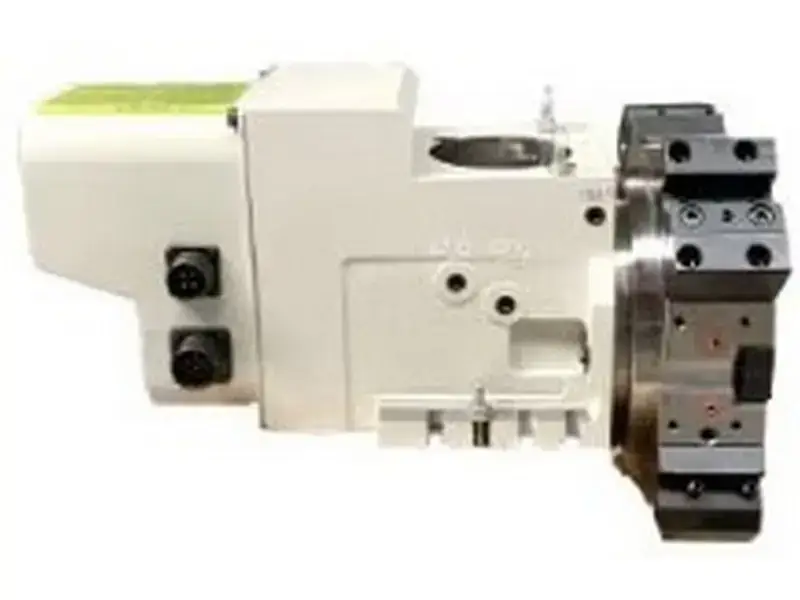

SLT Series 8 12 Station Tool Tailstock Turret

Original price was: $5,200.00.$5,000.00Current price is: $5,000.00.

SLT Series 8 12 Station Tool Tailstock Turret

| Item | Details |

|---|---|

| machinery test report | Provided |

| application | MILLING CUTTER |

| video outgoing-inspection | Provided |

| standard | Other |

| core components | Bearing, motor |

| weight (kg) | 80 |

| Center height of turret | 63mm/80mm/100mm/125mm |

| Number of tool-path | 8/12 |

| Time 45 of changing tool | 0.8/1.1/1.4/1.8 sec |

| Time 180 of changing tool | 1.2/1.4/1.9/2.5 sec |

| Clamping force | 1200/2800/3200/5200 kg |

| hydraulic working pressure | 3.5+/-0.5 |

| Flow rate | 20/22/25/30 L/min |

| Indexing accuracy | +/- 4 |

| Accuracy of repeatability | +/- 1.6 |

| Net weight | 50/68/88/150 kg |

Description

SLT Series 8 12 Station Tool Tailstock Turret

SLT Series Servo NC Turret: Precision and Versatility for Modern Machining

In the evolving landscape of precision manufacturing, the SLT Series Servo NC Turret stands out as a state-of-the-art solution engineered to enhance the performance of CNC lathes and turning centers. This advanced turret system combines servo motor technology with robust mechanical design, delivering exceptional indexing accuracy, rapid tool changes, and customizable features—making it a top choice for industries such as automotive, aerospace, and precision engineering.

At the heart of the SLT Series’ performance is its adoption of a servo motor for tool disc translocation. This high-precision drive system ensures precise indexing accuracy, allowing for consistent and reliable tool positioning even in high-speed operations. The servo motor enables rapid tool changes, significantly reducing downtime between machining steps, and supports bidirectional translocation with nearest tool selection. This intelligent feature optimizes tool change sequences by prioritizing the closest tool to the current working position, minimizing unnecessary rotation and further boosting productivity in high-volume production environments.

The SLT Series incorporates a high-precision triple Hirth coupling paired with hydraulic clamping devices, a combination that delivers exceptional indexing accuracy and reliable clamping. The Hirth coupling, known for its ability to provide precise angular positioning, ensures that tools are aligned with minimal error, critical for applications requiring tight tolerances. The hydraulic clamping system adds robustness, generating sufficient force to keep tools securely in place during heavy cutting operations. This stability is essential when machining hard materials or performing aggressive cuts, as it minimizes vibrations and maintains consistent cutting performance.

A key design feature of the SLT Series is its precise deceleration mechanism, which reduces operational noise and enhances the turret’s ability to withstand high-torque loads. This mechanism ensures smooth and controlled movement during tool changes, preventing sudden stops that could cause wear or inaccuracies. The reduced noise level also contributes to a more comfortable working environment, making it suitable for extended use in busy manufacturing facilities. Additionally, the turret’s ability to handle high-torque loads expands its application range, allowing it to tackle demanding machining tasks with ease.

Versatility is a defining trait of the SLT Series, with the capability to produce turrets with 4, 6, 8, 12, or more stations according to specific customer needs. This flexibility ensures that the turret can be tailored to match the complexity of the machining tasks at hand, whether for simple, low-volume production or complex, high-volume manufacturing. Furthermore, both the tool disc and tool holders can be customized to meet unique requirements, enabling seamless integration with specialized tools or non-standard machining processes. This level of customization makes the SLT Series adaptable to a wide range of industrial applications.

Delving into its technical specifications, the SLT Series offers four variants with center heights of 63mm, 80mm, 100mm, and 125mm, catering to different workpiece sizes and machining requirements. The allowed number of tools varies across models, with options suitable for both small and large tool inventories. In terms of speed, the turret demonstrates impressive performance: rotating 45° and clamping takes 0.9 to 1.8 seconds, while rotating 180° and clamping ranges from 1.2 to 2.5 seconds, ensuring rapid transitions between tools.

Clamping force is a standout feature, with values ranging from 1200kg for the 63mm center height model to 5200kg for the 125mm model, highlighting the turret’s capability to handle heavy cutting forces. The hydraulic working pressure is consistent across all models at 3.5±0.5MPa, with hydraulic oil flow rates ranging from 20 to 30 U/min, ensuring adequate power delivery for reliable operation.

Precision is guaranteed with an indexing accuracy of ±4″ and a repeatability accuracy of ±1.6″ across all variants, ensuring consistent results across multiple machining cycles. The net weight, excluding the tool disc, ranges from 50kg to 150kg, balancing structural stability with ease of integration into various machine tool setups.

In summary, the SLT Series Servo NC Turret represents a perfect blend of precision, speed, and adaptability. Its servo motor drive, high-precision coupling, customizable design, and robust performance make it an invaluable asset for modern machining operations. Whether in high-volume production or custom manufacturing, the SLT Series delivers the reliability and efficiency needed to meet the demands of today’s competitive manufacturing landscape.